Straight wire drawing machine is a device used to process metal cable & wire, it can stretch high, medium and low carbon steel wire, stainless steel wire, copper wire, alloy copper wire, aluminum alloy wire etc. The material suitable for stretching : welding rod, welding wire (gas shielded welding wire, submerged arc welding wire, flux-cored wire), steel wire(high, medium and low carbon steel wire, stainless steel wire, prestressing steel wire, type steel wire, rubber house steel wire, spring steel wire, steel core etc), cable &wire (aluminum steel wire, copper wire, aluminum wire) alloy wire etc metal wire & cable.

1.Introduction

Straight wire drawing machine is a device used to process metal cable & wire, it can stretch high, medium and low carbon steel wire, stainless steel wire, copper wire, alloy copper wire, aluminum alloy wire etc. The material suitable for stretching : welding rod, welding wire (gas shielded welding wire, submerged arc welding wire, flux-cored wire), steel wire(high, medium and low carbon steel wire, stainless steel wire, prestressing steel wire, type steel wire, rubber house steel wire, spring steel wire, steel core etc), cable &wire (aluminum steel wire, copper wire, aluminum wire) alloy wire etc metal wire & cable.

2.Application Description

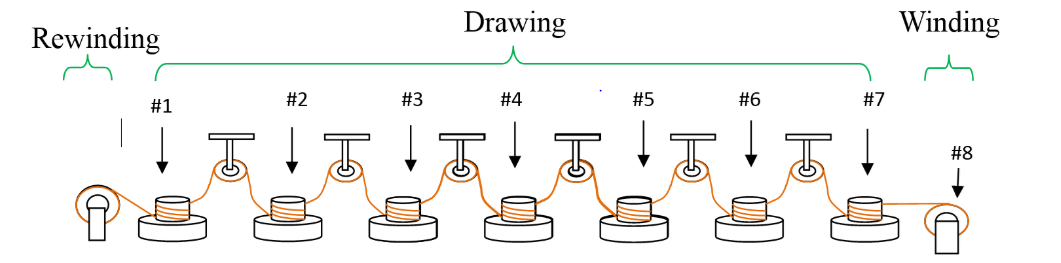

Straight wire strawing machine draws thick wire rod into thin metal cable through several process, this kind of machine compound with winding, multiple mold drawing, rewinding. For example, EN600 used to drive 8 inverter integrated system from No. 1 to No. 7 motor to finish 6 molding stretching, No. 7 wire plate output finished product to No. 8 wire plate.

3.EN600 application case

1、Case condition

On customer site, the straight wire drawing machine contain 8 motor drive, No. 1 to No. 7 motor used to drawing mold with power 18.5KW, No. 8 motor used to rewinding with power 7.5KW. The operator adjust speed with the rotary button on the operation panel, the main button control the motor from No. 1 to No. 7 plus each motor with fine tuning, No. 8 winding with independent torque given by potentiometer. The electrical configuration as below:

#1~#7 motor configuration:EN600-4T0185G/P works under speed mode with analog speed provision

#8 motor configuration:EN600-4T0075G/P works under torque control mode with analog torque provision

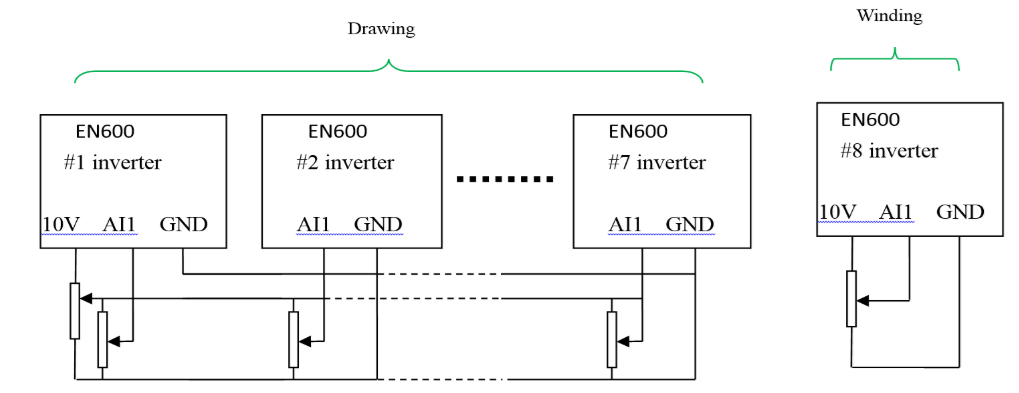

2、Electrical control wire diagram

8x EN600 adopting 0~10V voltage given speed, No. 1 to No. 7 use together main control potentiometer plus each with fine tuning potentiometer, No. 8 with independent speed control by potentiometer.

3、Customer application photo

4、EN600 parameter setting

EN600 straight wire drawing machine parameter setting as below:

| Drawing motor with parameter setting | |||

| Function code | Function name | default | Setting value |

| F01.00 | Main frequency input channel selection | 0 | 1 |

| F01.12 | Low limit frequency | 0.4 | 2 |

| F01.15 | Run command channel selection | 0 | 1 |

| F01.17 | Acceleration time 1 | | 100 |

| F01.18 | Deceleration time1 | | 100 |

| F08.18 | Input terminal X1 function selection | 1 | 1 |

| F08.19 | Input terminal X2 function selection | 2 | 3 |

| F08.20 | Input terminal X3 function selection | 0 | 4 |

| F15.01 | Asynchronous motor rated power | | Setting parameter as motor actual condition |

| F15.02 | Asynchronous motor rated voltage | | |

| F15.03 | Asynchronous motor rated current | | |

| F15.04 | Asynchronous motor rated frequency | | |

| F15.05 | Asynchronous motor rated speed | | |

| F15.06 | Asynchronous motor pole couple No. | | |

| Winding motor with parameter setting | |||

| Function code | Function name | default | Setting value |

| F00.24 | Motor control mode | 0 | 1 |

| F01.11 | High limit frequency | 50 | 60 |

| F01.15 | Run command channel selection | 0 | 1 |

| F01.17 | Acceleration time 1 | | 80 |

| F01.18 | Deceleration time 1 | | 105 |

| F07.01 | AI1 given gain | 1.004 | 0.15 ~ 0.25 ( winding diameter load lighter, no need big torque command, it can be adjusted as requirement ) |

| F08.18 | Input terminal X1 function selection | 1 | 1 |

| F14.00 | Speed/torque control selection | 0 | 1 |

| F14.13 | Torque given channel selection | 0 | 1 |

| F14.14 | Torque polarity setting | 0 | 1100 |

| F14.16 | Torque control forwarder speed limited channel selection | 0 | 2 |

| F14.17 | Torque control reverse speed limited channel selection | 0 | 2 |

| F14.20 | Setting torque acceleration & deceleration time | 0.1 | 25 |

| F14.21 | Torque compensation | 0 | 8 |

| F14.30 | Torque compensation cut-off frequency | 0 | 50 |

| F15.01 | Asynchronous motor rated power | | Setting parameter as motor actual condition |

| F15.02 | Asynchronous motor rated voltage | | |

| F15.03 | Asynchronous motor rated current | | |

| F15.04 | Asynchronous motor rated frequency | | |

| F15.05 | Asynchronous motor rated speed | | |

| F15.06 | Asynchronous motor pole couple No. | | |

| F15.07 | Asynchronous motor stator resistance | | Static tuning or rotation tuning without load |

| F15.08 | Asynchronous motor rotor resistance | | |

| F15.09 | Asynchronous motor leakage inductance | | |

| F15.10 | Asynchronous motor mutual inductance | | |

| F15.11 | Asynchronous motor current without load | | |

4.EN600 parameter setting

1 .Simple operation system with high stability, can chose the drawing coefficient randomly.

2 . Smooth start, can full utilize the torque control under vector mode on the winding & rewinding motor.

3 Long distance wiring between panel and inverter, there is no any protection to the wiring on site.

4 .EN600 can suitable both on straight rough drawing or medium drawing system.